Wood core Raised Access Floor Panels

Wood core/chipboard flooring system is made of high-density composite wood core glue to and encased in hot-dipped galvanized formed steel sheets. These chipboard raised access floor tiles have a class A flame spread rating and provide excellent rigidity, durability, and acoustic performance. Wood core access floor panel system consists of high-density (720Kg/m3) chipboard. Galvanized steel sheet/aluminum foil is bonded to the bottom of the chipboard. HPL or PVC is stuck to the top of chipboard, four edges are sealed with PVC edging strip.

woodcore raised floor China have gained significant traction, owing to their exceptional durability and versatility. Crafted with a robust wooden core, these raised floor panels possess the structural integrity to withstand heavy loads and the demands of high-traffic areas. The wooden core also provides a stable foundation, ensuring a level and consistent surface that can accommodate a wide range of applications, from data centers to showrooms.

Complementing the versatility of woodcore raised floors, the Chinese market has also witnessed a surge in the popularity of oak floating floors. These elegant, wood-based flooring systems offer a classic and timeless aesthetic that is well-suited for both residential and commercial applications.

Finished Floor Height : | 100- 2000mm |

Density : | 720 kg/m3 |

Panel Size : | 500* 500mm、600* 600mm、800* 800mm and special size |

Core Panel Thickness : | 30mm、38mm(16- 38mm can be customized according to project needs) |

Upper Covering : | Bare、1.0-2.0mm Anti-static Laminate HPL、2.0-3.0mm PVC、10mm Cermic、Marble、 Granite、 Nature Wood、and etc. |

Under Covering : | Bare、0.3-2.0mm Galvanized steel、0.1-2.0mm Aluminum Foil |

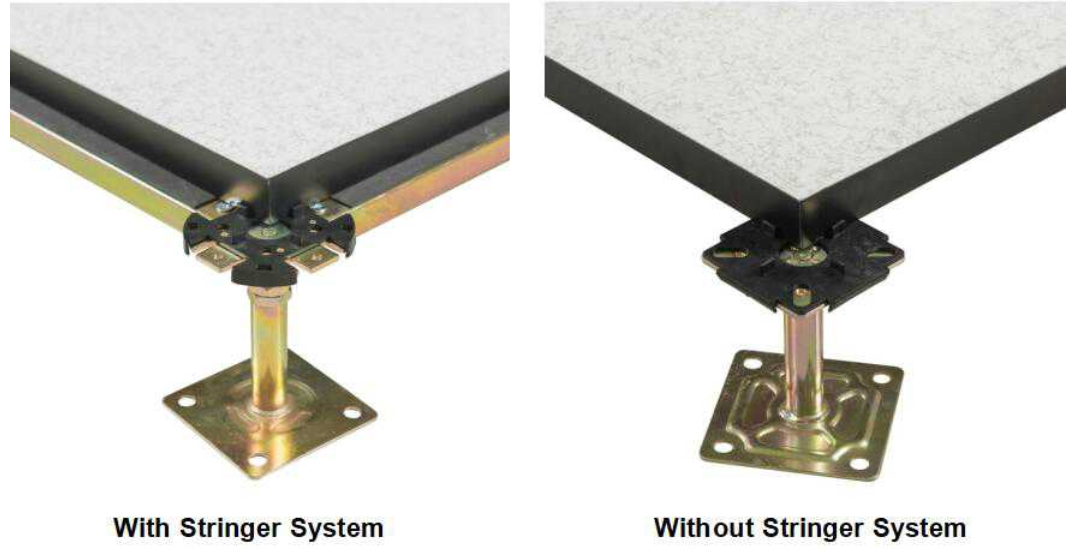

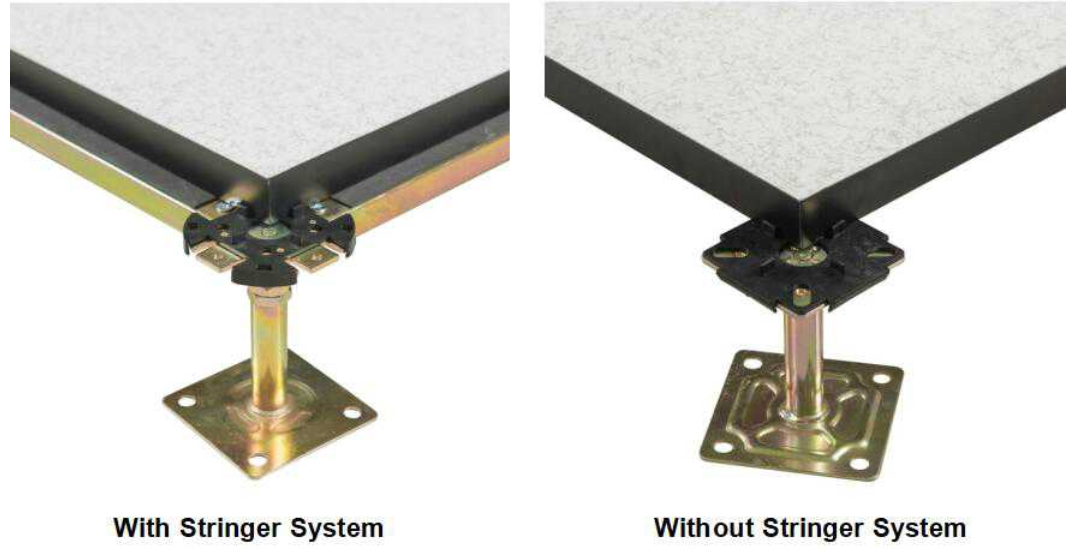

|Installation : | Without or With Stringer System |

Woodcore raised floor panels Benefits

● Natural and Beautiful: The wood is naturally green and pollution-free. No harm to the human body, environmental proof.

● Flexible and anti-skid: Our chipboard raised floor panel has a good anti-skid effect, it’s relatively safe and not easy to slip.

● High wear resistance and durability: Our raised wood floor panels are smooth and easy to clean without much maintenance and peacekeeping.

● Hard texture: ZiLi wooden raised access floor has good loading capacity.

● Good sealing and water-proof: The top surface is stuck with High-Pressure Laminate (HPL) or Conduct PVC or granite, the bottom is covered with aluminum foil or galvanized steel sheet. Four edges are sealed with black PVC edge trim.

● Customize the access floor solution according to local conditions, help customers save costs of Wooden Access Floor System while ensuring high quality, and buy the most satisfactory raised floor at the most affordable wooden raised floor prices.

Woodcore raised floor panels Application

The Woodcore raised floor panel applies to high-grade rooms, such as:

- Banks

- Telecommunication centers

- Smart offices

- Computer rooms

- Areas of high humidity

Customized Covering

Type | Size | Concentrated | Impact Load | Ultimate Load | Uniform Load | Rolling Load |

International | mm | N | N | N | N/M2 | 10 | 10000 |

Light duty | 600*600 | ≥2990 | 670 | ≥8890 | ≥12500 | 2215 | 1548 |

Medium duty | 600*600 | ≥3596 | 670 | ≥10799 | ≥19796 | 2959 | 2215 |

Heavy duty | 600*600 | ≥4498 | 670 | ≥13494 | ≥23294 | 3596 | 2959 |